In rolling mills there is a multitude of positioning tasks, for example alignment operations in side compression or shears positioning. At coil boxes, precise speed feedback is crucial for even wind and unwind of long metal sheets. The encoder PMG10 is particularly designed to endure the high load impact on loopers.

Speed and position feedback at coil boxes

At coil boxes, precise speed feedback is crucial for even wind and unwind of long metal sheets, sometimes without using spindles. Reliable speed feedback allows for synchronized and harmonized individual roll speeds. Furthermore, constant product geometry requires position control at the bending rolls.

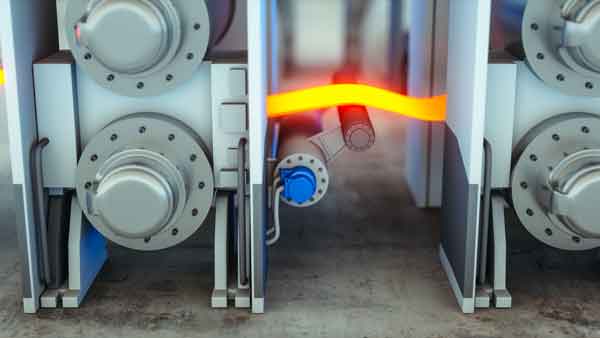

Position feedback at loopers

In the milling process, loopers control the amount of strain at the sheet metal between the rollers. They prevent any excess material building up in front of the roller and this way significantly contribute towards process stability. The narrow measuring angle of less than 90° causes the ball bearings being exposed to onesided load. PMG 10 bearings are particularly designed to endure such unbalanced load impact and furthermore provide specialized greasing that endures any temperature within the wide range. Extreme resistance against shock and vibrations provide long-life capabilities and durability in harsh environments.

Downloads

Brochures / Catalogs

-

Brochure – Encoders for steel and metal industry