China

cn

中文

给您带来的益处

- 通过精准测量实现精确定位

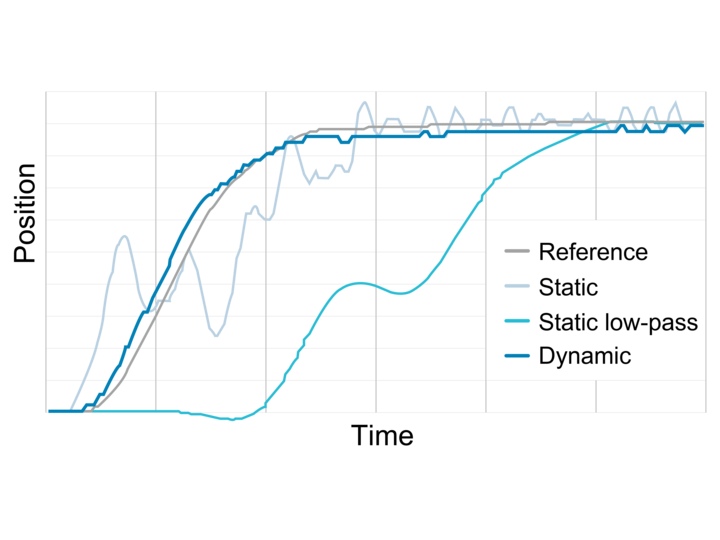

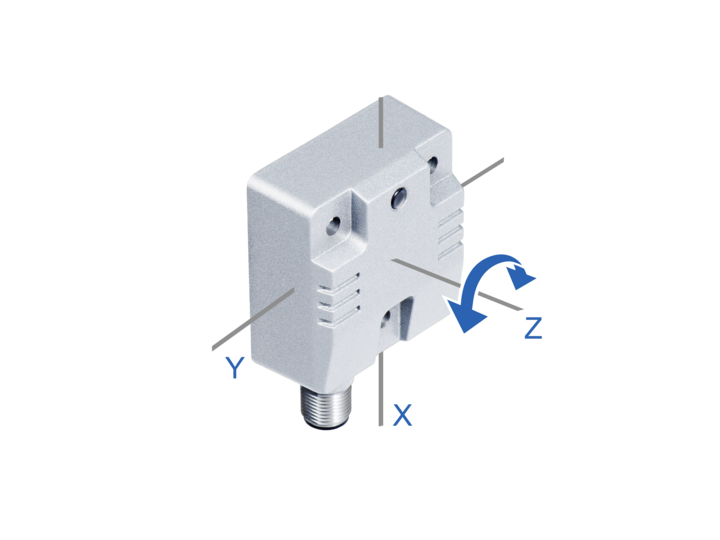

- 绝对精度高达±0.3°(动态精度高达±0.5°);强大的创新算法对加速度和陀螺仪信号进行传感器数据融合,实现快速响应

- 在恶劣环境中可靠运行

- 工作温度范围更广:-40 ... +85 °C;抗冲击和抗振动能力高达 200 g / 20 g;IP69K防护等级;防腐等级达CX(C5-M);设计符合E1标准

- 设备连接简单可靠

- 倾角仪自带CANopen®和SAEJ1939接口,支持CiA DS 410设备协议、M6螺纹式安装和坚固的M12接头

- 简化操作,提高机器效率

- 实时动态测量活动机械部件的角度位置;出色的信号质量、高分辨率、小到可忽略不计的跟踪误差确保高精度的测量;进行机器控制和使用辅助系统时,提供出众的动态性、控制性和安全性。

应用领域

在下列机械中实现轻松、可靠的角度测量:

- 移动机械

- 非公路机械

- 建筑机械、农用机械和林业机械

- 消防车和市政工程车

- 工作平台

- 起重机和吊装设备

- 无人驾驶运输系统

- 自动装配和加工机械

- 机器人

技术

Precise, motion-compensated position

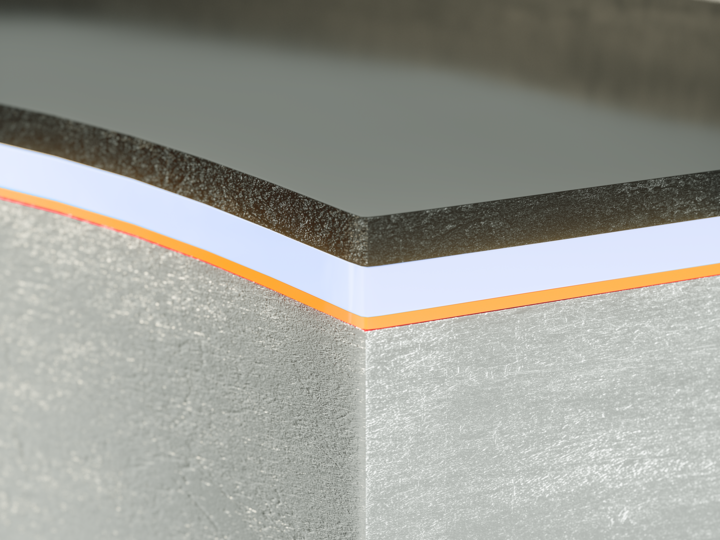

Reliable mounting and durable function

Robust R-series “designed for mobile automation”

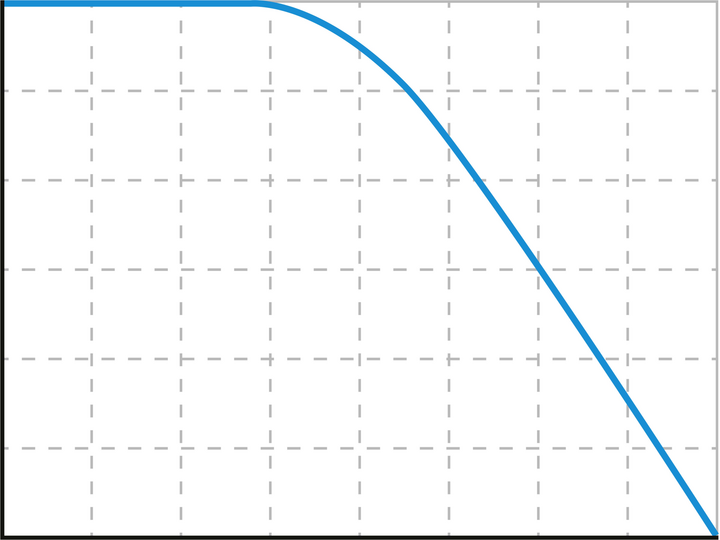

Configurable frequency filters

Outstanding corrosion protection

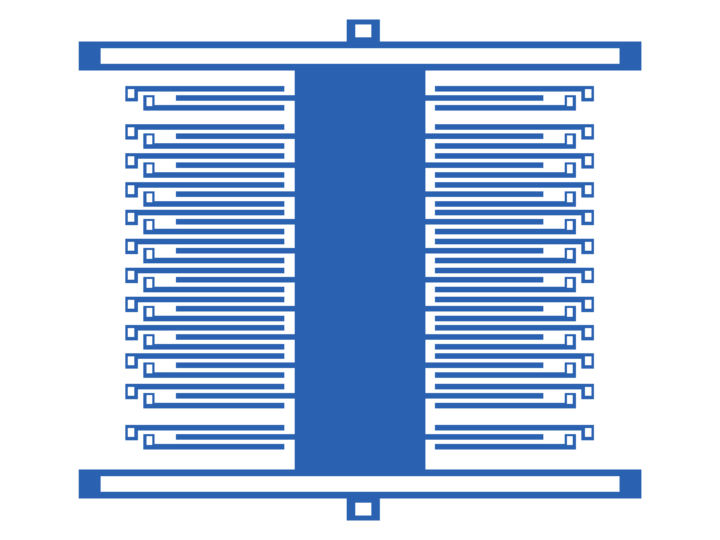

倾角仪的功能原理

MEMS技术

下载

手册 / 产品目录

-

手册:动态倾角传感器 GIM700DR