China

cn

中文

给您带来的益处

- 设备设计紧凑

- 轴向感应编码器非常适合轴周围空间有限的应用

- 即使在恶劣工况下也能长期可靠运行

- 坚固的无磨损磁感应技术

- 不受污垢、振动和冲击影响

- 不受轴承载荷影响

- 不受轴电流影响

- 安装在大功率电力驱动装置上的旋转编码器的滚珠轴承可能因电流过冲而损坏

- 感应头与轴分离有效解决了这一问题

- 长期保持高防护等级

- 采用无轴承设计,具有高性价比和高防护等级

- 即使在高速运转时,编码器也能防止水和灰尘的侵入

- 电子元件和活动部件分离,提高了坚固性

- 专为工程机械自动化而设计

- 设计符合E1标准,具有出色的抗电磁干扰能力

- 电缆采用0.5平方芯线,可预装工程机械专用接头(如德驰连接器)

应用领域

Steering angle detection for AGVs

垃圾车车厢的倾角测量

起重机当前转角输出

通过摆杆转角进行张力控制

技术亮点

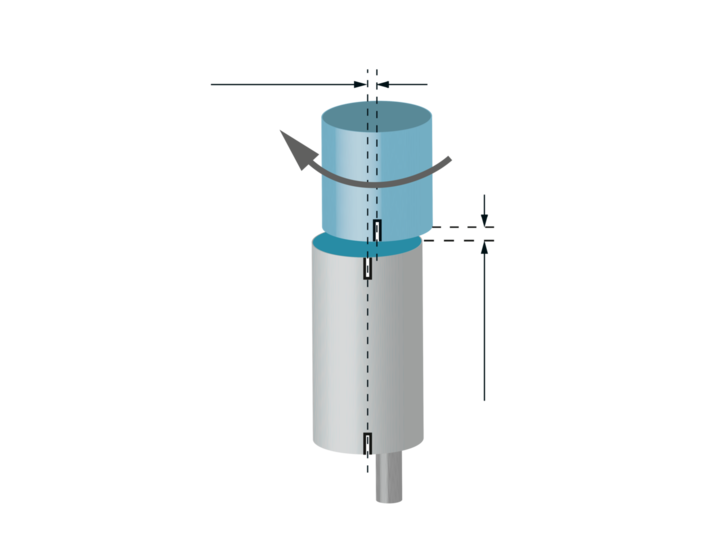

由于采用磁感应技术,感应头和磁体(这里为磁转子)之间无需安装轴承。因此,二者可以分开安装。同时,这种设计还允许较大的安装误差,从而提高设计和安装的灵活性。此外,没有轴承,也就没有常见的磨损现象。这样,编码器能有效抵御灰尘、污垢或纺织纤维,不受轴电流或轴承载荷的影响,具有出色的抗振动和抗冲击能力。

坚固耐用,安如磐石

Functionality of axial sensing

Mounting with axial scanning

Permanently high IP protection class

下载

手册 / 产品目录

-

手册:旋转编码器和角度测量选型指南