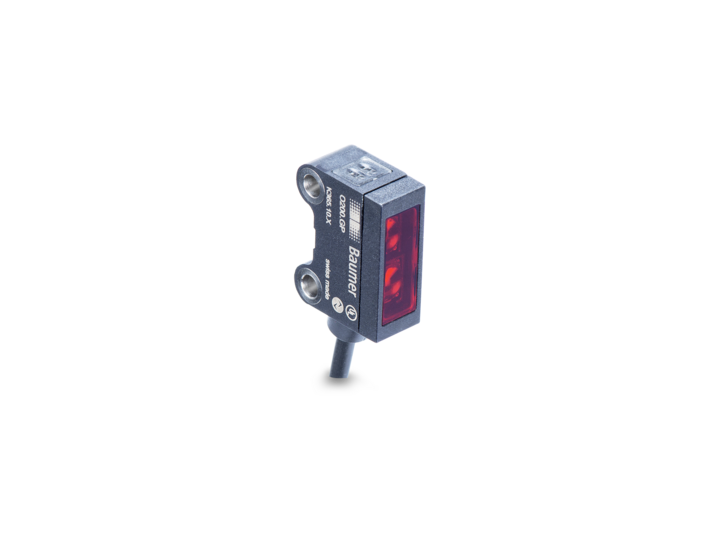

SmartReflect light barriers

SmartReflect optical sensors by Baumer are suitable for reliable level control in the vibrating spiral feeder. Thanks to their design and intelligent signal processing, they detect objects reliably and without contact, regardless of their color or shape.

High performance reserves thanks to powerful processors

- Trigger safely even with highly reflective parts

- Extremely dirt-resistant

Easy installation and start-up

- Teach-in takes place on the bottom of the container. When the light beam is interrupted by parts, the switching output is activated

- Automated parameterization with IO-Link

- Simple and well-guided qTeach® teach-in method allows rapid training, saves time and improves protection against manipulation, or by potentiometer

- Universal push/pull sensor with selectable mode (NO / NC) reduces the number of different parts in stock

Flexibility in machine design

- The Baumer OneBox Design allows for easy exchange between optical and ultrasonic sensors of the U500 and O500 series thanks to an identical housing

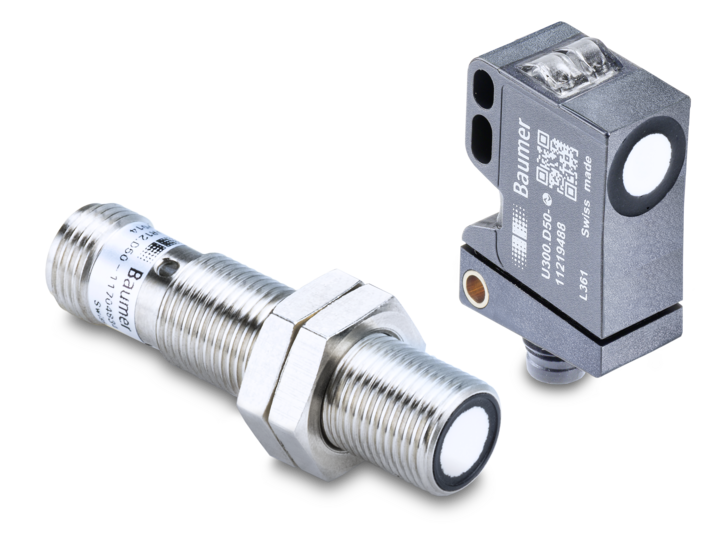

Ultrasonic sensors

Ultrasonic sensors detect the parts in the hopper, regardless of their color or transparency properties. The characteristic of the sonic cone allows reliable level detection even in the case of cluster-forming parts, such as longer pins or rivets. Variants with one or two independent switching signals as well as an analog measuring signal are available.

High process reliability with a large range of parts

- Independent of object color, gloss, or transparency

- Unsusceptible or highly resistant to dust, dirt and moisture

- U500 and UR18 are uniquely resistant to chemical and mechanical influences, thanks to the hermetically sealed sensor element

- Sensor adjustment to the properties of the object, thanks to parameterization with IO-Link

Flexibility in machine design

- Cylindrical or rectangular design allows installation in practically any installation situation

- Miniaturized sensors for minimal interference contours

- Short blind regions allow measuring almost up to the sensor surface

Easy installation and start-up

- Automated parameterization with IO-Link

- Simple and well-guided qTeach teach-in method allows rapid training, saves time and improves protection against manipulation

- Universal push/pull sensor with selectable mode (NO / NC) reduces the number of different parts in stock

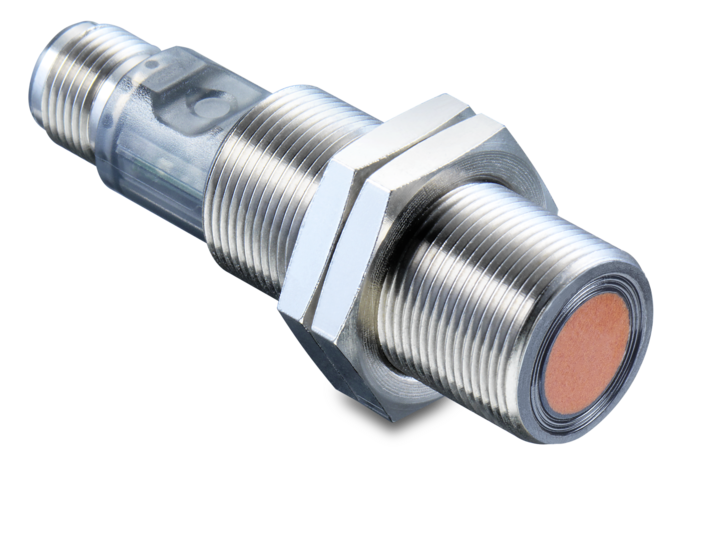

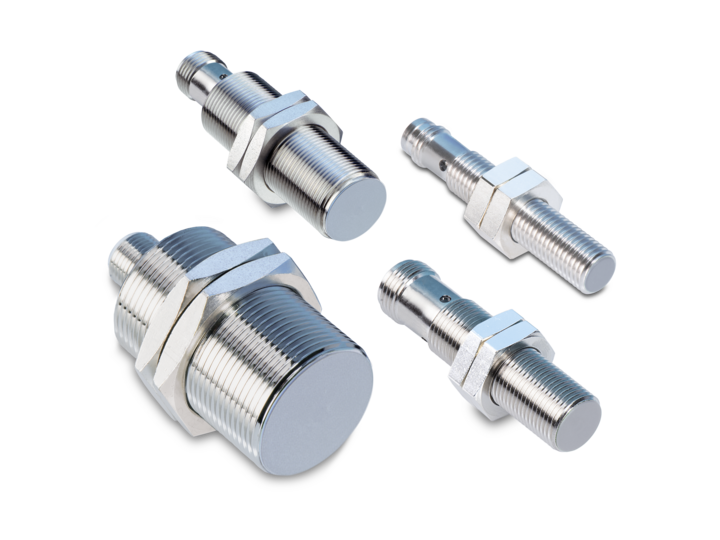

Inductive proximity switches

To use in conjunction with the sensor arm on your level control device. Baumer offers a very wide range of inductive proximity switches. With their robust metal housing and fully encapsulated electronics, inductive sensors guarantee robustness and process reliability, even in applications exposed to vibrations.

High process reliability even in demanding environments

- High repeat accuracy and precise switching point

- Vibration resistant encapsulated electronics

- Robust metal housing

- Independent of object color

- High degree of temperature stability and very good EMC properties

Flexibility in machine design

- Large selection of sizes and shapes allow installation in practically any installation situation

The IFFM20 inductive sensor with a particularly large sensing distance is ideal for detecting the level of metallic parts in vibrating spiral feeders made of plastic.

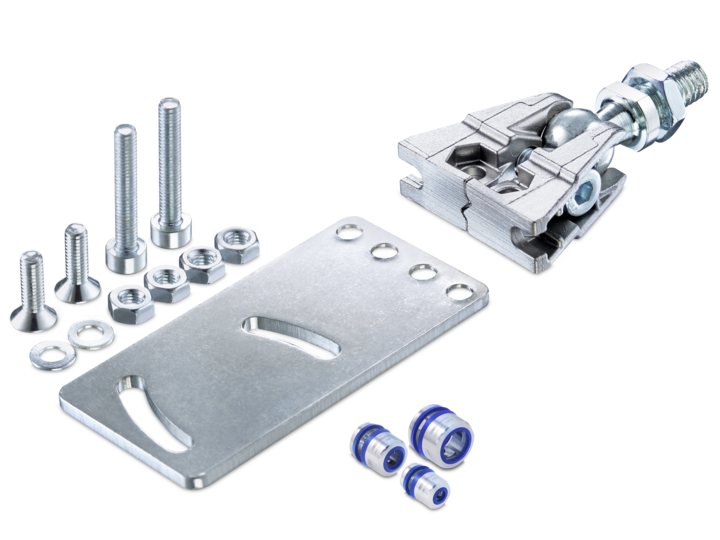

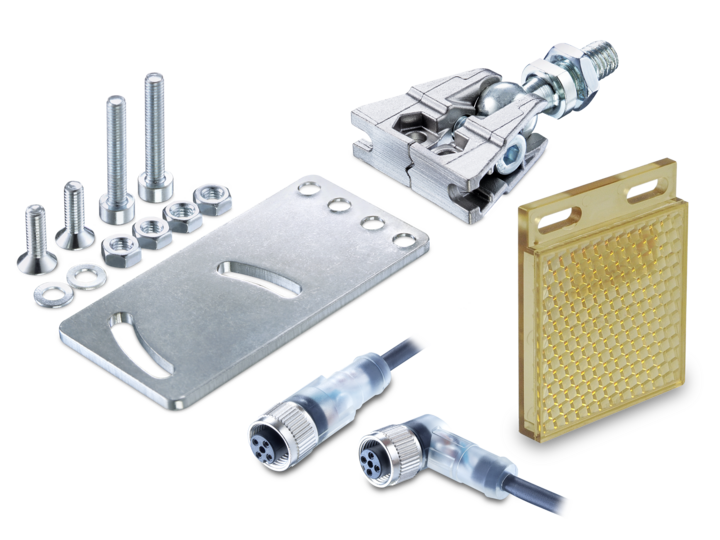

Discrete assembly from below

- Gentle, non-contact detection

- Free access from above without wiring getting in the way

- Very small footprint thanks to flat and compact design

High process reliability

- Reliable detection of metal parts such as washers or nuts through the plastic floor thanks to the extra large sensing distance of up to 8 mm

- Metal housing with encapsulated electronics for maximum robustness, particularly in applications exposed to vibrations

- High repeat accuracy and precise switching point

- High degree of temperature stability and very good EMC properties